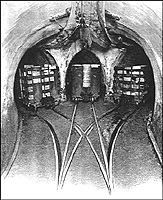

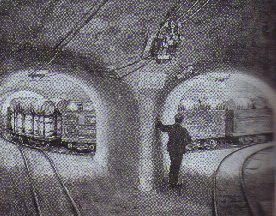

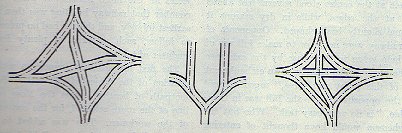

A typical 3 way junction on the Chicago Freight Subway

A 3 way junction.

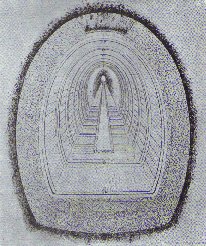

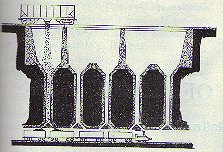

Cross section of the tunnel.

|

Overview:

Location:

Timespan:

Description: |

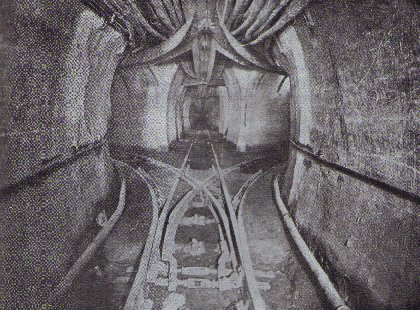

A test train around a junction. It is said this picture was taken for promotional purposes. |

Timeline:

|

While London, New York, and other large cities have been busy building and extending their subterranean railway tracks to accommodate the ever increasing travelling public, Chicago has quietly constructing an underground railway for the express purpose of carrying its freight. On this unique system not a single passenger is transported, only goods and mails. Far below the surface of the street electric locomotives are busy day and night hauling thousands of tons of merchandise, mails, coal, ashes, garbage, and debris, without noise, without dirt, doing the work well and expeditiously. When it is stated that there are now some 60 miles of track in operation, covering the whole of the business district of the city and the greater portion of the principal residential quarter, it will be understood that this is no ordinary railway enterprise, but one designed to meet some special need, and for that reason it is well worthy of notice.

The Need of the System:

Chicago, owing to its topographical formation, found its freight traffic congested more than its passenger.

With no fewer than twenty-five trunk lines running into the city, Chicago's freight

tonnage traffic is enormous, and this is confined within a comparatively small area-not more

than a mile and a half square. In this district teamsters' trucks and wagons constantly

block the way-or rather did so before the advent of the underground railway, and

caused such congestion of traffic that business was often paralyzed for hours at a time.

The city authorities were at a loss to know what to do. It was impossible to change the termini

of the trunk lines, and the trafic was doubling itself every decade. For two years or more, the

municipality discussed ways of relieving the condition of the streets, but, as

often happens, it was left to private enterprise to find a solution-in the construction

of a freight subway.

Imagine for a moment what such a railway would mean to London, or to any other city, and you may grasp how it has revolutionized the street traffic of this American city. All the goods and parcels for a great warehouse would be right into its basements by the underground railway having connections with the leading railway depots. In the same way the various post offices would send their mails from one office to another by this route. The great stores would deliver a large portion their goods by the subterranean road ; while all coals for the hotels on the line of the route would be conveyed by rail, and the ashes and garbage removed in the same expeditious manner.

The construction of a network of lines far below the surface of a city's streets is in itself a difficult feat, but in the case of Chicago the engineering problems to be overcome were of the most perplexing character. The city is built on a vast deposit of soft clay, of a consistency resembling that of cheese. Heavy buildings havo to be supported on piles or concrete piers, which pierce this clay until they finally reach bedrock, from 80 to 120 feet below the street level. The weight of many of these buildings is enormous ; and while it was not contemplated that the tunnels should go under them, but under the middle of the streets on which they are abutted, there was a possibility of the removal of the amount of material necessary for the bores through the centre of the street, and the tremendous weight resting on each side, might lead to settling and straining of the buildings, or even total collapse. How real this danger was the construction of the New York Subway demonstrated at a later date, when several buildings were entirely wrecked because of the excavations in the street which they faced.

It is one of the most astonishing facts in the history of the Chicago Tunnel construction that, though the work lasted seven years, though every street in the business section of the city has been tunnelled, and some 60 miles have been constructed, there has been not a single claim for damages on the part of any property owner.

No Settlement of Ground reported:

There certainly have been settlements, or supposed settlements, along the

route, but experts competent to judge have declared that these subsidences were not

due in any way to the construction of the tunnels. Again, it is gratifying to record that

in the erection of the subways no lives were lost. In a report recently issued by

Mr. George W. Jackson, the general manager and chief engineer, reference is made to

these points as follows : " So, many misleading, malicious, and vicious reports have been

circulated about damages being done by this Company's work, that I feel it my duty to state

emphatically that the construction of the entire system has been accomplished without the

Company being called upon to defend or pay any claim for damages of any kind. No deaths

have occurred that can be attributed to tunnel construction, and not one employee has been

disabled to such an extent as to prevent him from following his usual vocation."

Another interesting fact about this unique undertaking is that the capital of

£10,000,000 required to build the subterranean freight road, was subscribed privately,

no stocks or bonds being offered to the public.

As a matter of fact, the work was done so quietly that very few people in Chicago itself realized what had happened until the newspapers announced that a wonderfully complete and up-to-date underground railway system had been built under its streets, and would shortly be opened for trafic. This was not because the engineers went about their task in secret and purposely avoided publicity.

Telephones and Tunnels:

The original promoters of the scheme were the owners of a telephone company, known as the

Automatic. The most striking feature of this telephone are that it does away with operators at

the central station, that a subscriber calling up another subscriber is able to make his own connection

and that when two persons are talking together over the wires it is impossible for a third to " butt in "

or listen to the conversation. Mr. Albert G. Wheeler, the engineer for this particular Company, who

reallr planned and carried to a successful issue the tunnel subways, when making an application

to the City Council for a franchise, made it for the Illinois Tunnel and Telegraph Company, now

known as the Illinois Tunnel Company. If anything was said before the City Committee about the

subject of handling freight in the tunnels it was merely incidental, and excited no particular interest.

The franchise as granted eventually, specified that tunnels were to be constructed and used for

the transmission of "sound, signals, and intelligence by means of electricity or otherwise".

The distribution of newspapers or letters, for instance, comes under the head of

"intelligence," but one would not expend millions in building a tunnel system for the

purpose of handling one paper or one letter. Papers and letters must be treated in bulk

and as freight. All that the authorities stated at the time was that the tunnels were

high and wide enough for a man to work in comfortably, with ample space for

for the suspension of the telephone wires from the roof and side walls, and planned

to meet the future growth of the system. They also stipulated that the subways were to be some

40 feet underground. This was an exceedingly wise condition, as it permits the construction ,

should it ever be needed, of a tunnel for passenger trains between the street level and the subways,

the floor of the latter feet being 46 feet below the surface.

Surveying the streets:

Having obtained permission, the engineers commenced operations. The first thing was to survey

the line of route. Every street in the business section of the city was surveyed thoroughly, the engineers

refusing to accept the existing maps, many of which were found to be faulty. As observations could not be made

on week-days, streets were choked with traffic of every description, the work had to be done on Sundays.

For the sake of speed and economy, it was necessary to operate from serveral widely separated points

simultaneously. At each of the points selected a shaft was sunk at tunnel level, and drifted out to of

the street, whence excavation in both directions on the axis of the tunnel. Most of these shafts were

sunk in the basements of buildings rented by the Tunnel Company, and fitted up as workshops. Here concrete

was mixed and lowered to the tunnels, and air-compressing machinery was installed.

The tunnels are of two distinct types - trunk tunnels and lateral conduits. The former follow the main routes of freight traffic. The latter run out to the less important parts of the city, and in time will reach the suburbs, and end in small conduits adapted only to accommodate telephone and other wires. The main or trunk line tunnels are 14 feet 6 inches from crown to floor, and 12 feet 9 inches wide at the base ; while the laterals are 7.1/2 feet high and 6 feet wide. The trunk subways have 18-inch cement walls and 21-inch cement floors ; the smaller tunnels 10-inch walls and 13-inch floors. At the top and sides of these subways are strong cables containing telephone wires, while the floors are left free for freight traffic.

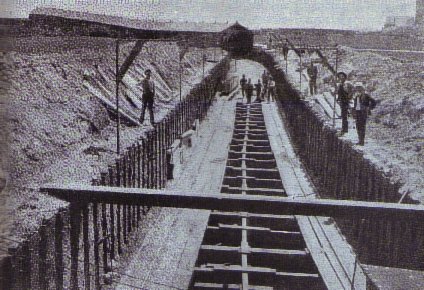

Building the Subways:

Active excavation began on September 1, 1901, and by November 1904 twenty miles of track had

been laid and made ready for use. An ingenious system of excavation was adapted as affording a

safeguard against labour troubles. In the system, there is no possibility of "caving in" or collapse

should a strike occur and workmen be unobtainable. A description of the plan followed on the 6-by-71/2 foot

conduits will give an idea of how the excavations were made and the concrete subway installed.

The bore in the clay was dug considerably larger than the dimensions of the finished subway. The mining was done by men with hand tools, the material being removed subsequently by mule teams. After the excavators had finished their labours the cementing gang appeared. Their first task was to place in the bottom of the tunnel the required concrete, tamp it thouroughly, and lay on top of it a lagging of boards. This done, they placed at intervals of three feet steel ribs of the size and shape of the inside of the tunnel. When these ribs were in place, a lagging of 2-inch planks was placed between them and concrete packed in behind the lagging in layers of six inches, so as to fill up the entire space between the wood and the walls of the excavation.

In this way, subsidence of the ground was avoided, because no matter how irregular was the mining, every void was filled. This method was followed to the top or key of the arch, where to ensure absolute accuracy, the key-blocks were formed of two lagging boards only three feet long, the use of short sections ensuring better work. After the ribs and lagging had been removed, the concrete was given a facing of cement to seal all crevices.

In the larger, or trunk, lines a somewhat different process was followed steel lagging plates being used instead of planks,

and 5-inch instead of 3-inch channel for ribs. The work was done in sections only three feet long, the steel lagging plates

being of just sufficient length to span the 3-foot section of the ribs.

How the Works progressed:

The tunnelling was effected by three shifts of men working eight hours each, the first two shifts doing mining work and the

third shift concreting. About 850 men were engaged in the three shifts. In this way the tunnel was mined and cemented at the

rate of more than 300 feet per working day, or considerably over a mile a month. More than 300,000 cubic feet of material

was excavated in a period of three years, and about half the quantity of stone, gravel and cement was put in place. As many

as thirty-eight connections had to be made between different tunnels, and so accurately was the surveying done that in no

instance was a junction an inch out of truth. An air pressure of about 8lbs. to the square foot was maintained throughout

the tunnel during the construction period, this being found sufficient to prevent the water from encroaching as the work progressed.

The excavated material was removed in a novel manner. At various points along the street "head houses" were erected. Here the loaded the cars from the tunnele beneath were brought up through vertical shafts, and their contents were dumped into wagons to be transported to the lake front. This carting of material through the city was done at night only. The dirt was utilized for reclaiming nineteen acres from the lake and adding them to the city's park, without one cent of expense to the park authorities. The Tunnel Company now run cars to the surface at the "dump" by means of an inclined railway connecting with their system.

Removing excavated material:

Wherever a big building has been erected in Chicago during the past two years the subway has been employed to haul away

the material excavated from the foundations. This is accomplished by simply running up from the tunnel to the excavation

shaft about three feet in diameter. The workmen wheel their barrows of soil into the yawning mouth and empty them into it.

As these shafts make an angle of about 45 degrees with the horizontal, gravity carries the débris to the bottom

where it falls into a waiting car. One car filled, another is moved under the mouth of the chute, and when a train has been

made up an electric locomotive hauls it away to the lake front. By this method the subway has moved from the basement of one

building alone 2,100 cubic yards of material in twenty-four hours. The best record by teams in the same time is 420 cubic yards,

and to do this even it was necessary for the contractors to stop their overhead work entirely.

Direct Connection with Warehouses:

As already stated, when the system was declared open in November 1904, 20 miles of lines had been laid. By September last the

mileage had increased to just over 60. Naturally, the greatest revenue from the operation of the tunnels comes from the

transportation of freight. There is more freight hauled through the streets of Chicago than through any other city of America.

New York hauls about 75,000 tons of freight daily, Philadelphia and Boston about 65,000 tons each, Chicago 100,000 tons.

The underground railways do not expect to move all this freight, but are prepared to take one-third or more of it if they can get it.

This branch of the business is now being pushed forward energetically, but the authorities had to educate the merchants and

manufacturers to the advantages of the subways. First of all they offered to install, free of charge, in any of the large warehouses

and stores along their route special shafts and elevators, to connect these establishments with the subterraneans railways. The first

fifty installed cost 200,000 pounds. But these houses find them invaluable. The cars of the underground system bring goods direct

from the railway depôts to the basement of the buildings, whence elevators raise them to the desired floor.Of course, this direct

connection between tunnel and warehouse is not always possible, so the railway authorities have built central depôts at various

places throughout the city, so that a shipper is not obliged to haul his merchandise more than a few hundred yards.

Two years ago the subway officials secured from the postal authorities a contract for the transportation of mails. This contract was obtained only by convincing the powers that be against their will of the advantages by the new system. The main post office building in Chicago is the heaviest edifice in the city, and its enormous weight is supported by piles driven down to bderock. When the engineer first approached the postal officials with a proposition to connect the building with the tunnel system, so that the mails might be carried from one office to another undergound, they scouted the idea, saying that any such conection would undermine the building, cause a settlement and probably result in its entire collapse. To prove that they were wrong, the engineer constructed a subway right under the centre of the structure. In places this tunnel had to go through the piles on which the building rests and the result is that the subway actually rests on the bottom portion of these piles, and the top part of the piles on the crown of the tunnel. After this work had been completed, the engineer invited the postal officials to take a trip through the tunnels as his guests. They accepted the invitation, and one can imagine their surprise when the car was suddenly stopped, and they were informed that they were right under the post office building. For two days, it is said, the leading surveyors of Chicago were busy examining the edifice critically, but could not find a crack or a piece of plaster that had been disturbed. The post office stills rests as solidly on its foundation as does the rock of Gibraltar. Not long afterwards the tunnel people secured the contract spoken of.

For this mail work the railway employs 66 electric motors and 115 cars. In 1907 the electric trains made 337,060 trips with mails through the subways to the various branch offices, railway stations, etc., transporting 10,659,567 bags, pouches, and packages of postal matter. The record for this tremendous services was "99.51 per cent perfect" - that is to say, in this proportion of cases the mail delivered was delivered at the proper station in time. Last Christmas Eve the Company handled without a hitch, 44,341 bags of mails, 5,911 pouches, and 195 packages - a total of 50,447.

Extent of Subways and Equipment:

In the construction of the tunnels the Company has burrowed under the river in fourteen places. Its lines now reach from Armour

Avenue and Archer Avenue on the south to Chicago Avenue and Kingsbury Street on the north, and to Green Street on the west. The

equipment consists of 250 motors and 2,500 cars ; but of course, these are added to as needed. Both engines and cars are of a special

pattern. The locomotives are of the class used in the mines and have a wheel base of 241/2 inches. Two sizes of engines are employed

- the smaller one boasting 75 horse-power motors and weighting about 3 tons ; the larger ones being 80 horse-power, and turning

the scale about 5 tons. The cars, 4 feet wide and 101/2 feet long, reach 63 inches above the rail. Their individual capacity is

30,000 lbs. They are of iron and steel construction, with double trucks and eight wheels. The gauge of the line is 2 feet. The steepest

grade in the subways is 1.75 per cent, and the gradients at the railway terminals do not exceed 12 per cent. The latter grades form the

approaches to the tunnels. The largest intersections, known as a four way sections, where the track branches off in three directions,

have curves of 20-foot radius. The curves on the main lines, however, are of 16-foot radius. There is a complete drainage system. A

telephone station on every block enables the movements of the trains to be controlled entirely by telephone. The whole subway is lighted

electrically, and has a twenty-four-hour service.

To-day the sybways are owned by a corporation in which railway interests are largely represented. High praise is undoubtedly due to Mr. Albert G. Wheeler, the engineer who conceived and carried to a successful completion this remakable and interesting underground freight road ; and also to his able lieutenant, Mr. George W. Jackson, the general manager. Recently Mr. J. Ogden Armour and Mr. E. H. Harriman joined the board of the Illinois Tunnel Company. The presence of Mr. Armour, whose interests and name are so intimately associated with all that makes Chicago a synonym for enterprise, is in itself a guarantee that the best interests of the city will be served by the Tunnel Company. Coupled with that of Mr. Harriman who is recognized in railway circles to-day as one of the greatest living constructive geniuses and financial managers on the American continent, the success of the subways seems to be assured.

© 1998-2001 by Frédéric Delaitre

Created: 98/02/25

Last Modified: 01/06/24